25 March 2024, Seoul, Republic of Korea – SAIGE is proud to announce the launch of its enhanced deep learning-based machine vision solution, SAIGE VISION Version 2.1.

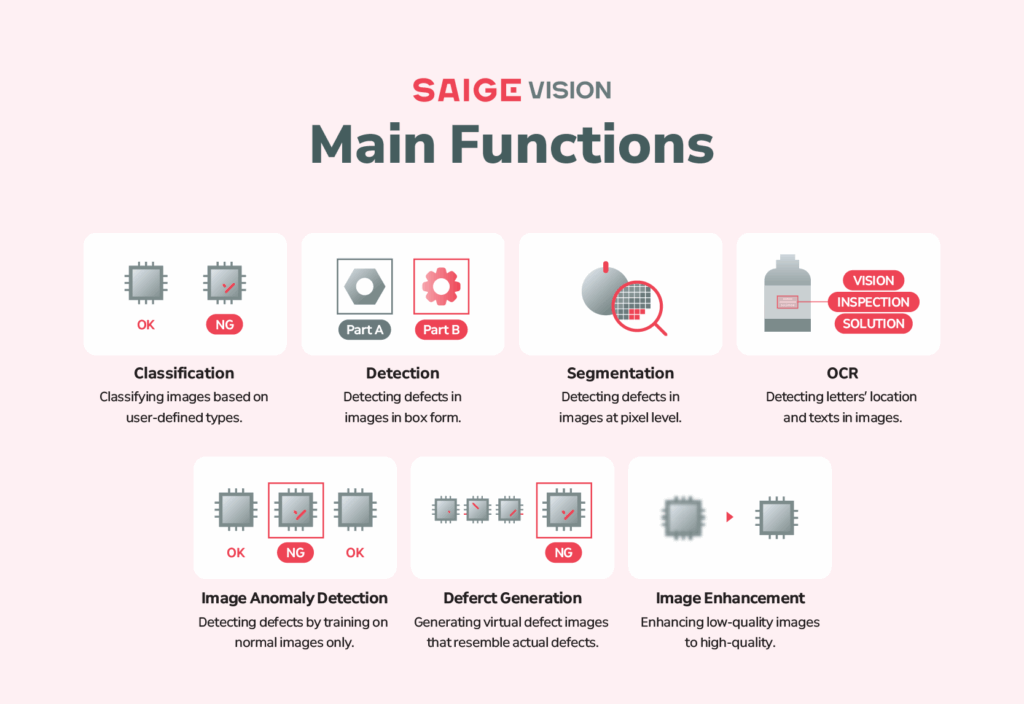

SAIGE VISION has been meticulously developed to address challenges unmanageable by traditional rule-based machine vision programs. This advanced solution autonomously detects surface defects in products, aiding in the determination of product quality. The latest upgrade introduces several innovative features:

Image Anomaly Detection: This feature identifies defective images by learning exclusively from normal samples, eliminating the need for predefined definitions. It minimizes labeling efforts through unsupervised learning.

Image Enhancement: This function upgrades low-quality or out-of-focus images captured rapidly by X-ray or CT to high-quality images, making them suitable for deep learning. This is particularly beneficial for integrating AI in the manufacturing industry, where acquiring high-quality images is often difficult.

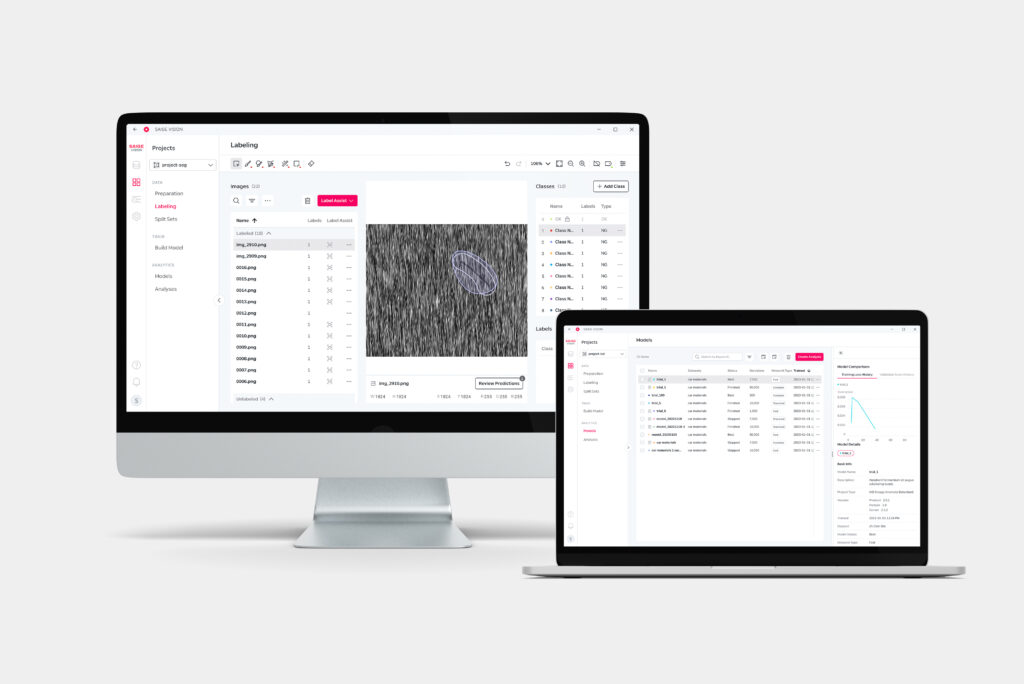

Auto Label and Quick Label: These updated features reduce the time and human resources required for labeling by automatically guiding and selecting defect areas with a simple click, replacing the previous manual process of marking each defect.

Additionally, existing features have been significantly improved:

Optical Character Recognition (OCR): Now standard in Version 2.1, OCR can detect English, Korean, numbers, and 33 special characters, and it has been enhanced to recognize additional languages and complex symbols through learning.

Defect Generation: This exclusive function generates higher-quality virtual defect images compared to previous versions.

Optimizer: By adjusting the program based on the environment, this function can increase inspection speed by up to five times, with an average accuracy improvement of 10%.

The overall inspection speed and accuracy have also been enhanced. With the application of the Optimizer, which adjusts the program based on the environment, inspection speed can be increased by up to five times compared to when this function is not used. Moreover, the accuracy of the new version has been improved by an average of 10% compared to the existing version.

Youngsuk Hong, Vice President of SAIGE, commented, “This upgrade of SAIGE VISION focuses on enhancing user convenience and optimizing for the manufacturing environment. We are dedicated to creating AI solutions that address the challenges of the manufacturing sector.”

The upgraded SAIGE VISION will be showcased at booth #C808 during the “Smart Factory + Automation World” event at Coex in Seoul, Republic of Korea, from 27 to 29 March 2024. / THE END.

© SAIGE All Rights Reserved.