Introduction

Quality control (QC) is a critical phase in the product development lifecycle, serving as the final opportunity to identify and eliminate defects. Among the various QC methods, vision inspection —- focused on detecting visual defects -— plays a pivotal role. Traditionally reliant on human inspection, this step is now increasingly augmented by advanced technologies to enhance efficiency and accuracy.

Challenges of Manual and Rule-Based Vision Inspection

Manual vision inspection, while effective, is inherently limited by human error and inconsistency. To mitigate these issues, rule-based machine vision systems have been integrated into many manufacturing processes. These systems utilize predefined algorithms to analyze images captured by cameras, offering speed and consistent standards of classification.

However, rule-based machine vision systems encounter their own set of challenges: (i) inflexibility and difficulty in adapting to new or complex defect patterns; (ii) difficulty in adjusting parameters for each new inspection device; (iii) over-detection, particularly in generating a high rate of false positives, causing unnecessary disposal of good products and increasing production costs.

The Emergence of AI in Vision Inspection

Artificial intelligence (AI) presents a promising solution to the limitations of rule-based systems. Leveraging the capabilities of deep learning, AI can handle a broader range of defects with greater accuracy and adaptability. This technology shift is exemplified by SAIGE and their innovative product, SAIGE VISION.

Case Study: Rechargeable Battery Manufacturing

In the rechargeable battery sector, precision in quality control is paramount due to the potential safety risks associated with defects. SAIGE VISION has been successfully implemented in this industry, demonstrating its capability to enhance QC at various stages of production. SAIGE VISION can also be introduced as a secondary inspection layer to complement any existing rule-based inspection process.

Electrode Plate Inspection Process: Implementation

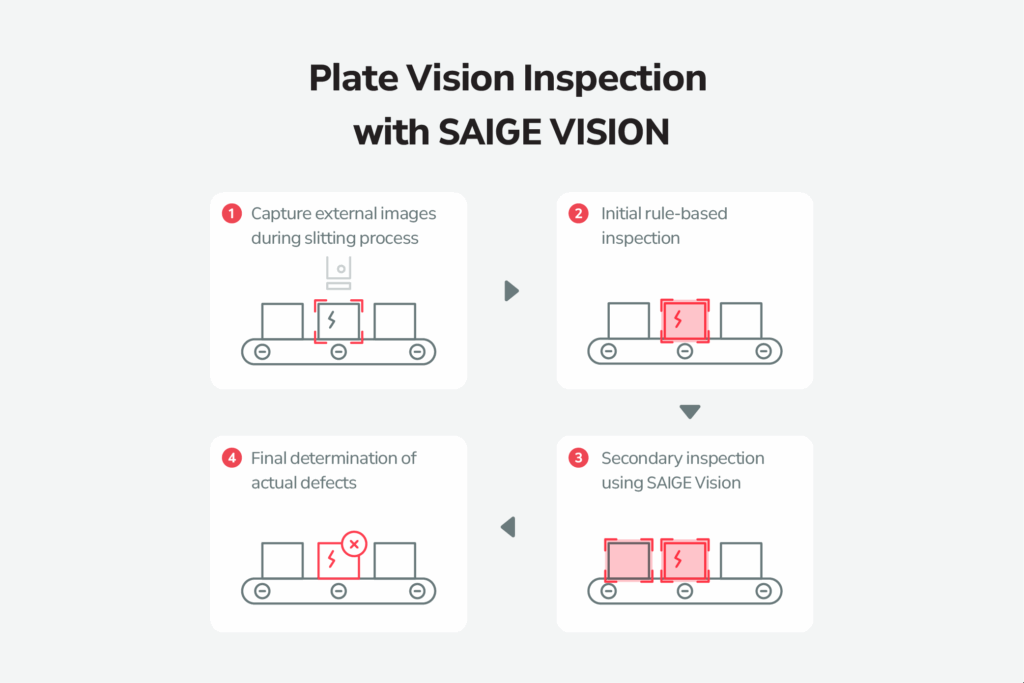

Steps to implementing SAIGE VISION into electrode plate inspection include:

- Image Acquisition: High-resolution line scan cameras capture detailed images during the slitting process, ensuring consistent directional imaging of the electrodes.

- Initial Rule-Based Inspection: The first inspection phase uses a rule-based algorithm to identify potential defect points.

- Secondary AI-Based Inspection: SAIGE VISION’s advanced classification and image anomaly detection algorithms perform a secondary inspection on defects detected by the initial rule-based system.

- Final Defect Determination: Combining the results of both inspections, a final determination of true defects is made, ensuring higher accuracy and reducing false positives.

Cell Assembly Inspection Using X-Ray and CT Images

In the battery cell assembly process, the presence of foreign metal or electrode fragments can lead to critical defects, compromising the safety and performance of the final product. Traditional X-ray inspection methods, which rely on rule-based algorithms, struggle with processing and analyzing X-ray images, and identifying internal defects and external foreign materials. SAIGE VISION’s advanced preprocessing and detection algorithms convert X-ray images into a format optimized for defect inspection, significantly improving detection

accuracy and reliability.

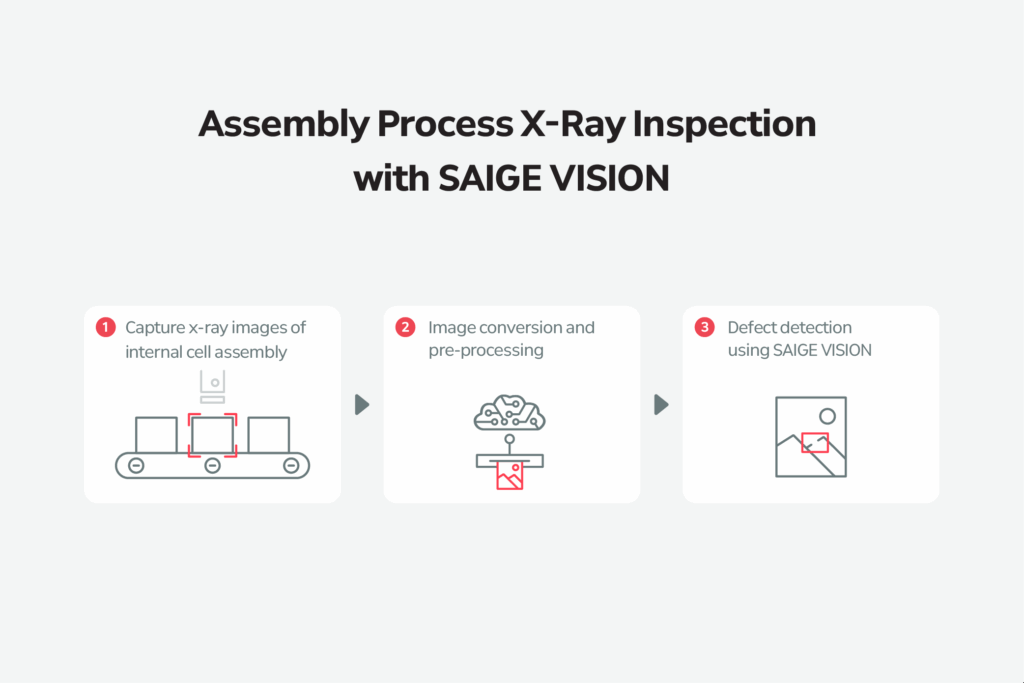

Steps to implementing SAIGE VISION into cell inspection include:

- Image Capture: Internal images of battery cells are captured using an X-ray device, providing detailed visuals of the cell’s interior.

- Image Conversion: SAIGE VISION’s preprocessing algorithm converts these X-ray images into a format that is optimal for defect inspection. This step enhances the clarity and detail of the images, making it easier to identify potential issues.

- Defect Detection: The enhanced images are analyzed using SAIGE VISION’s Detection algorithm, which accurately identifies and flags foreign materials and other critical defects within the cells.

Conclusion

SAIGE VISION represents a significant advancement in QC technology, particularly in industries where precision and safety are critical. By integrating deep learning, SAIGE has developed a solution that surpasses the capabilities of both manual and rule-based inspections. SAIGE VISION can be used both as the primary detection system and as a secondary layer of verification, effectively reducing over-detection rates while conserving materials and lowering overall production costs. As more data is processed, the AI model continuously improves, adapting to new defect types and production variations.

As AI technology continues to evolve, its application in vision inspection will undoubtedly lead to higher standards of quality and efficiency across various manufacturing sectors.

For more information on implementing SAIGE VISION in your production process, please contact us.

© SAIGE All Rights Reserved.