To create a smart work environment, it is essential to improve the way processes are operated. In terms of industrial safety, ensuring the safety of both workers and sites is crucial. Thorough management is necessary as accidents in factories or work sites can result in significant losses and even casualties.

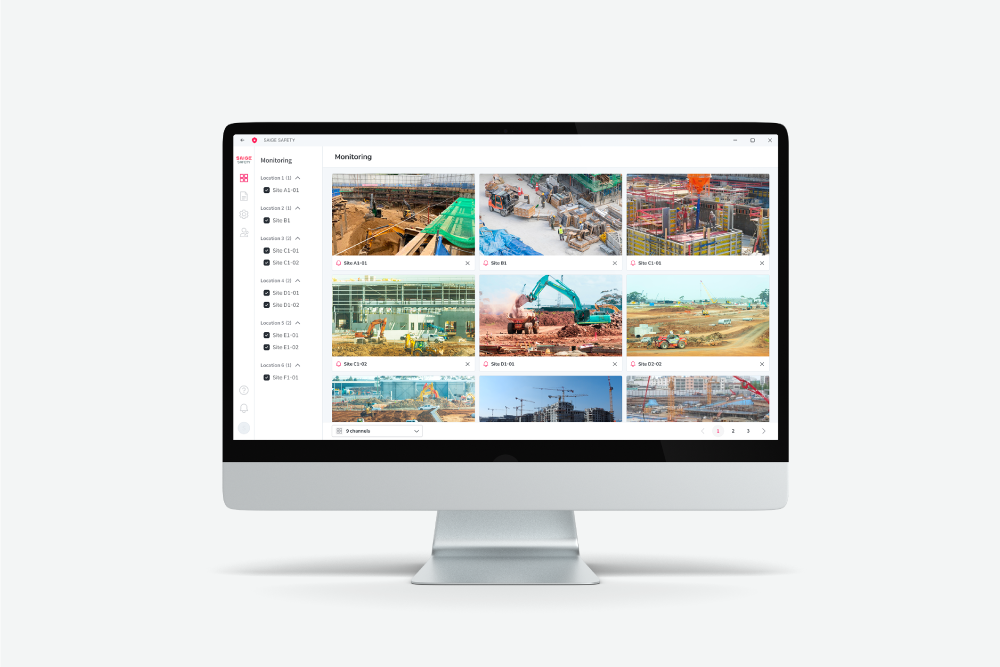

SAIGE SAFETY is an artificial intelligence-powered monitoring solution for ensuring safety at work sites. While SAIGE VIMS is a system that monitors the details of a process, SAIGE SAFETY takes a broader view and monitors the site in real-time to ensure there are no anomalies or problems throughout the site operation. With round-the-clock monitoring, you can manage site conditions and react swiftly when alerts are triggered, indicating anomalies that have been set by operators.

The scope of workplace monitoring varies widely. It includes preventing fatal accidents by determining if a safety helmet is being worn, detecting access to hazardous equipment, spotting a fallen worker and identifying intrusions from outside. It can even help prevent industrial accidents by identifying factors that could lead to a major incident, such as smoke or fire.

Challenges of Work Site Monitoring

While security cameras are installed to monitor work zones at construction sites which are particularly sensitive to safety, there are practical challenges to introducing AI. The biggest issue is that site conditions change real-time. Outdoor sites are especially heavily influenced by the weather, and the light level also constantly changes throughout the day. As a result, the quality of recorded footages can vary, posing difficulties for video analysis.

Another obstacle is that outdoor sites face limitations in communication speeds and hardware. AI analytics require high-end hardware and high-quality images, which may not be available out at sites. Therefore, it is impractical and costly to replace all the PCs or the security cameras to implement an intelligent monitoring solution.

An Intelligent Monitoring Solution Applied to Construction Sites

Despite such difficulties, SAIGE SAFETY has been successfully implemented in around 20 sites nationwide, taking responsibility for on-site safety management. It is especially equipped with an algorithm that is robust to environmental changes so that sites can be monitored and analyzed with the existing version without any new deep learning even when surrounding conditions or light levels change.

Due to its exceptional ability to detect anomalies compared to typical monitoring systems, user convenience has significantly improved. The fact that it provides immediate alerts in case of incidents also greatly enhanced safety accident prevention and management. Moreover, by minimizing false detections, the meaningfulness and usability of the detection information have been enhanced. With a growing dataset of analyzable data, you can examine what kind of circumstances lead to problems and identify causes in accidents.

A notable example is how conventional monitoring systems misidentify a person as a different individual if they pass by a pole, leading to information error. Normally, if a person without a safety helmet passes through a particular object and reappears, the system would recognize the person as a different individual. However, SAIGE SAFETY has a strengthened algorithm so that it can correctly identify a person passing through obstacles as the same person, thereby increasing information accuracy. With higher accuracy, situational awareness has improved, enabling immediate on-site responses.

SAIGE is working hard to use artificial intelligence to address various issues in the industrial sector. With SAIGE SAFETY, we have proven that industrial safety can also be advanced through AI. Algorithms and user settings optimized for site management will contribute to creating a safer work environment.

© SAIGE All Rights Reserved.