SAIGE VISION Inspection Areas

in PCB Manufacturing

-

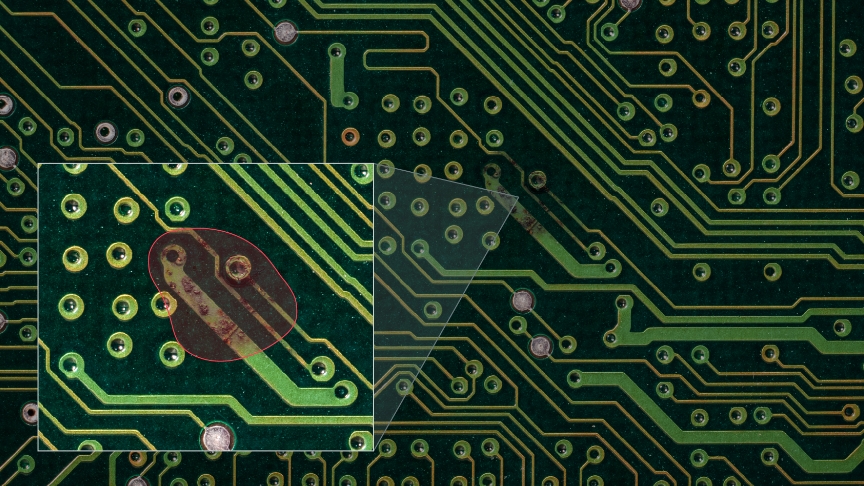

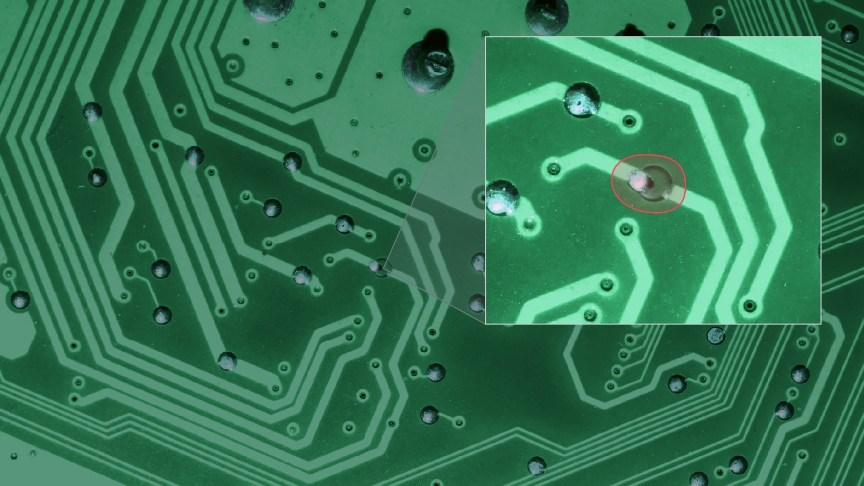

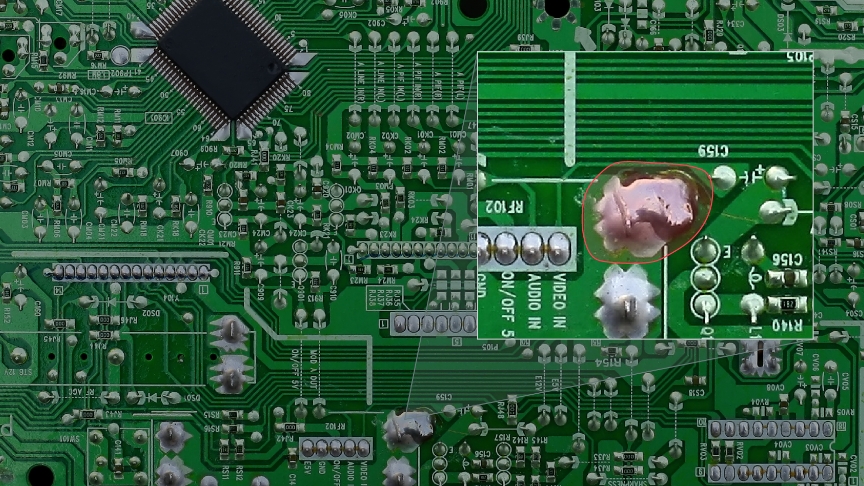

PCB Substrate Quality Inspection

In PCB substrate manufacturing, this stage ensures the quality of structural elements such as circuit patterns, layer alignment, drill holes, solder mask, and overall appearance. SAIGE VISION identifies even the smallest defects — from micrometer-scale alignment errors to subtle pattern flaws — at high speed and with exceptional accuracy. For high-density PCB production, AI-driven inspection is now essential to boosting both quality and productivity.

-

-

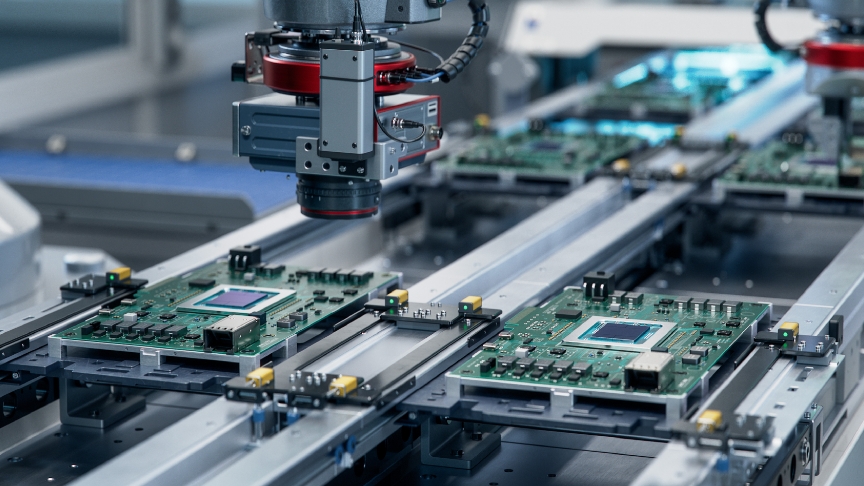

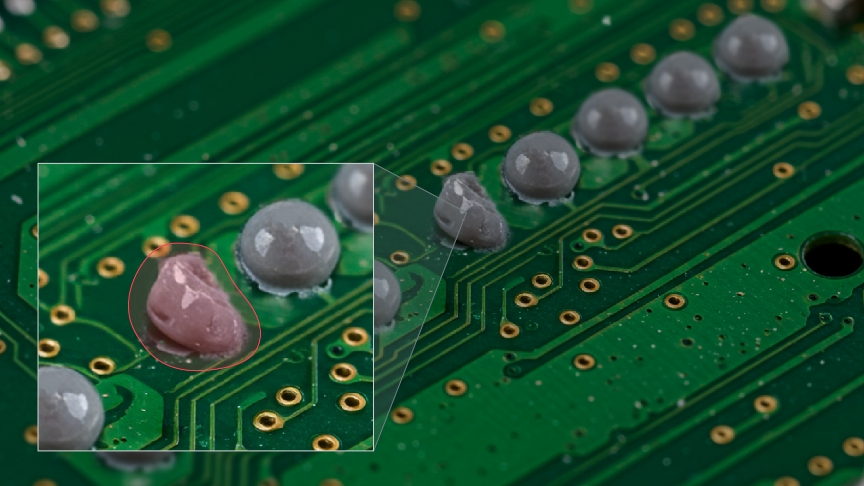

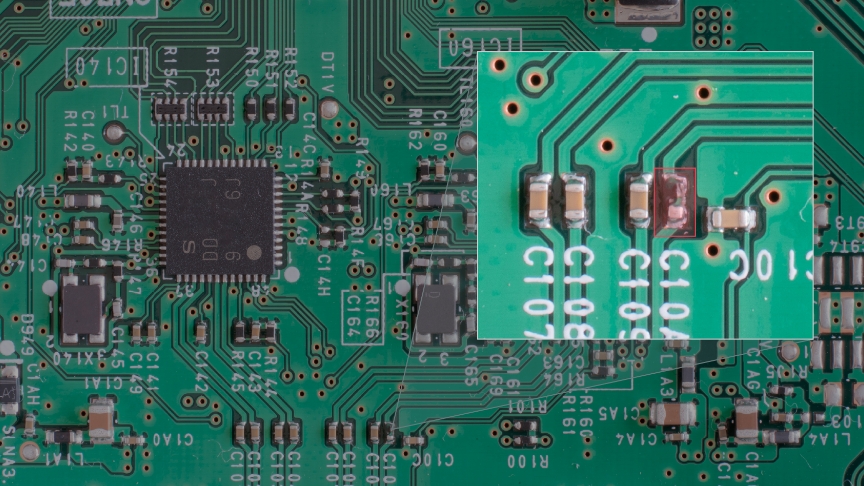

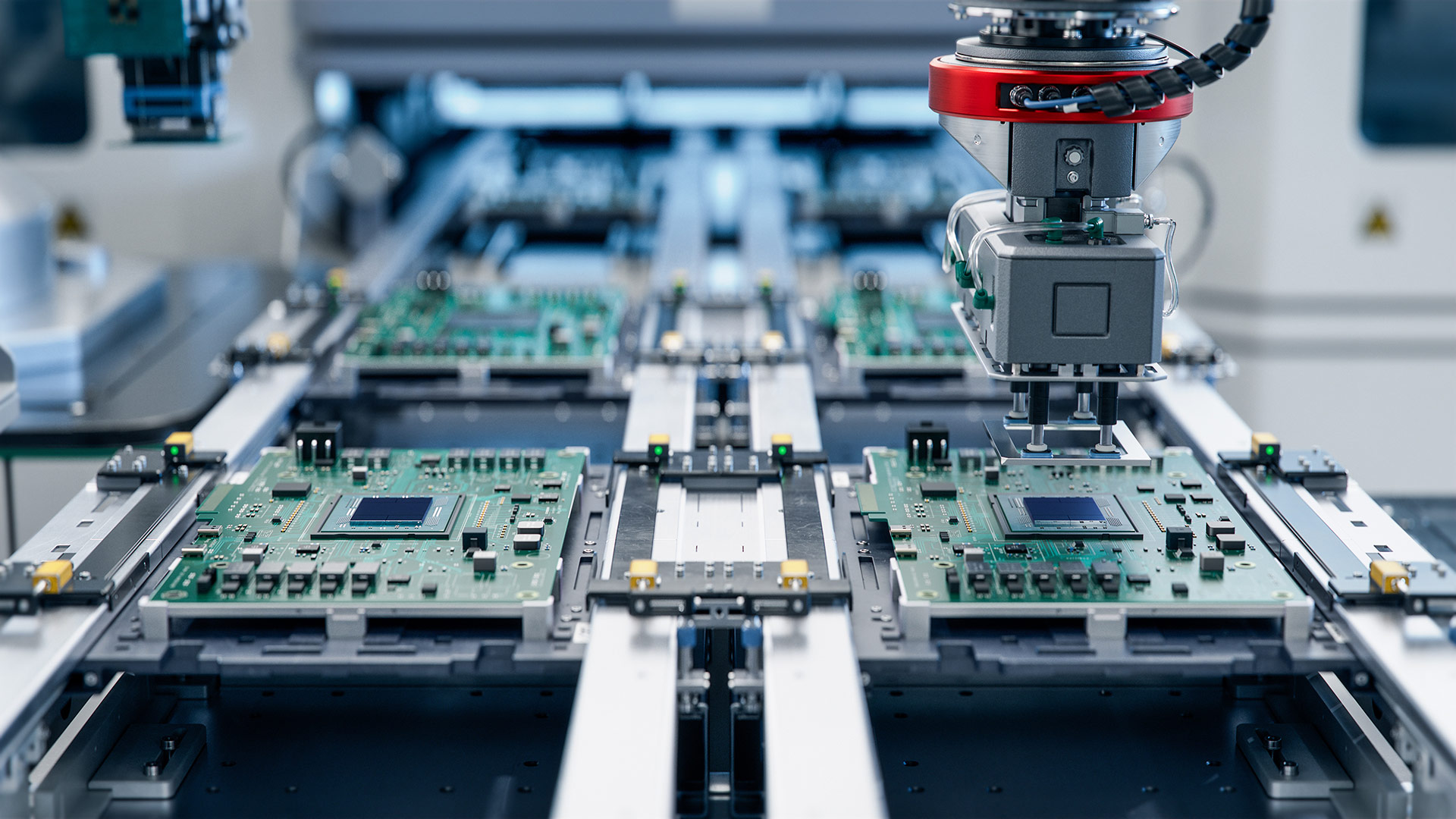

PCB Assembly Inspection

In PCB assembly inspection, SAIGE VISION ensures defect-free production by verifying precise component placement, detecting missing parts, and identifying soldering issues at every stage — from solder paste application to final connections. Powered by AI, it outperforms traditional methods even under reflective or changing lighting, delivering real-time feedback to fix errors instantly and cut defect-related costs.

-

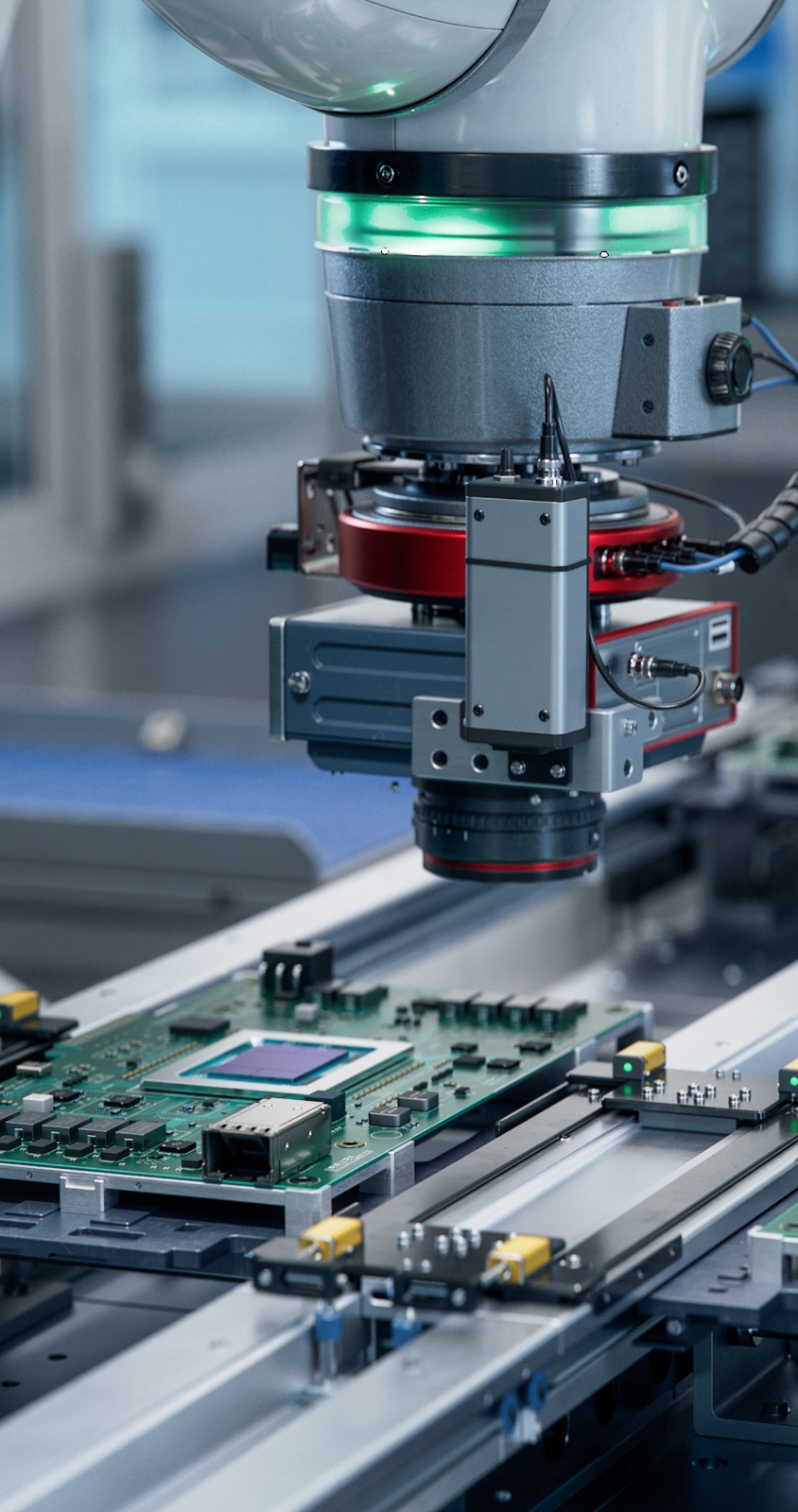

SAIGE VISION's fast and accurate vision inspection" />

SAIGE VISION's fast and accurate vision inspection" />