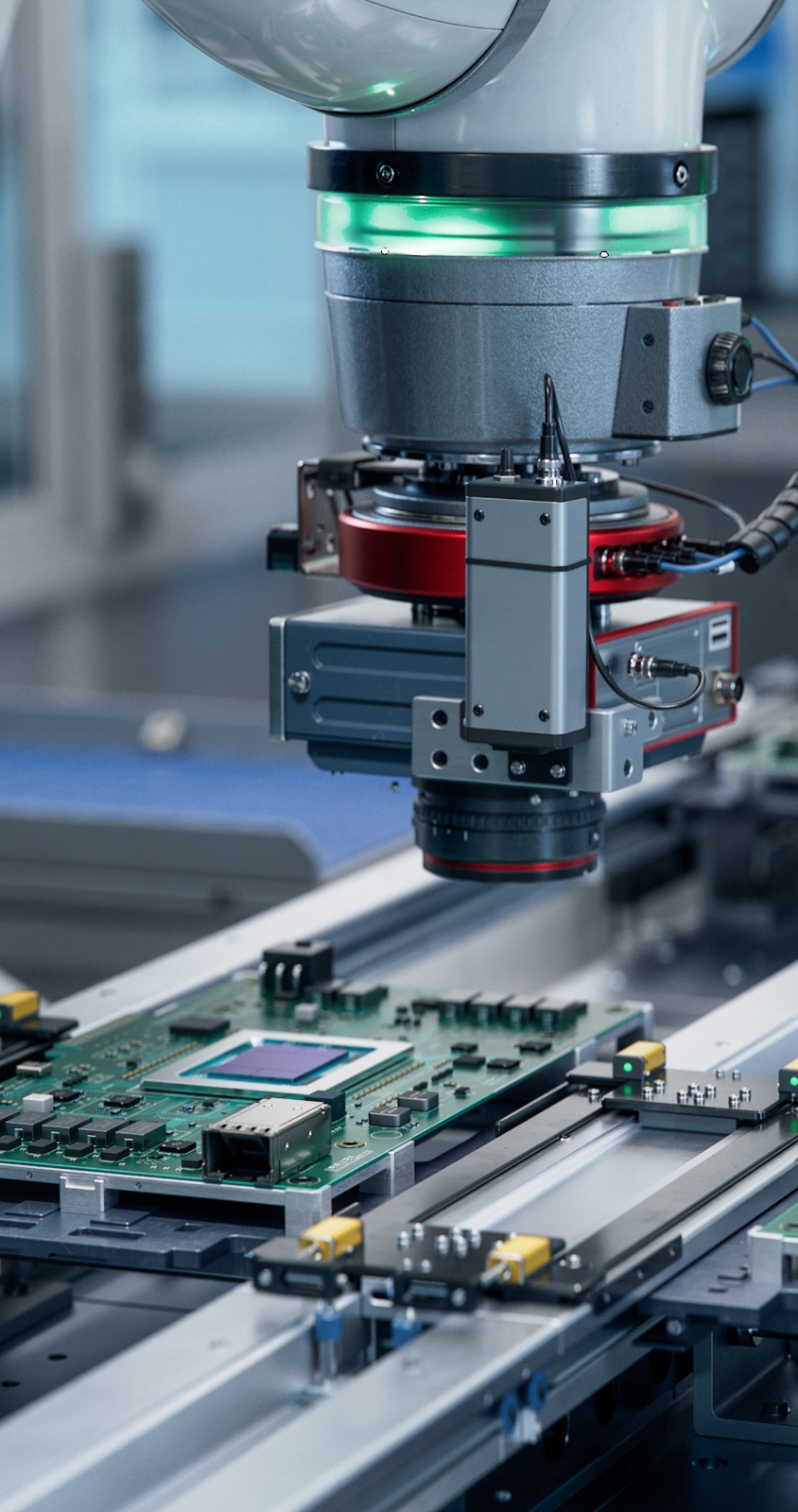

Solution

SAIGE VISION Inspection Areas

SAIGE VISION Inspection Areas

in Rechargeable Battery Manufacturing

Powered by manufacturing-optimized AI algorithms, SAIGE’s vision inspection solution delivers precise, reliable quality control across critical stages of Rechargeable battery production.

-

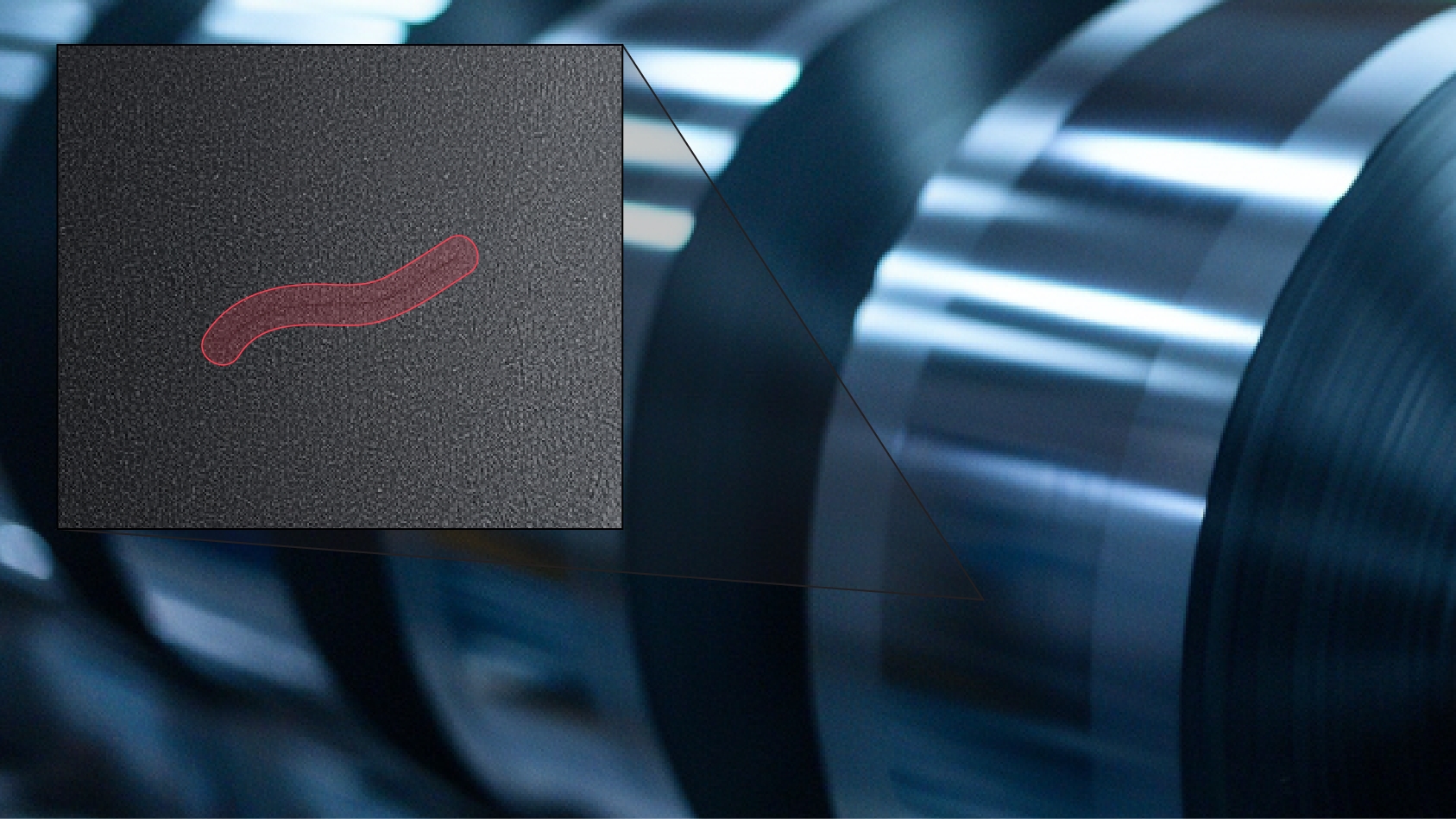

Electrode Process

-

-

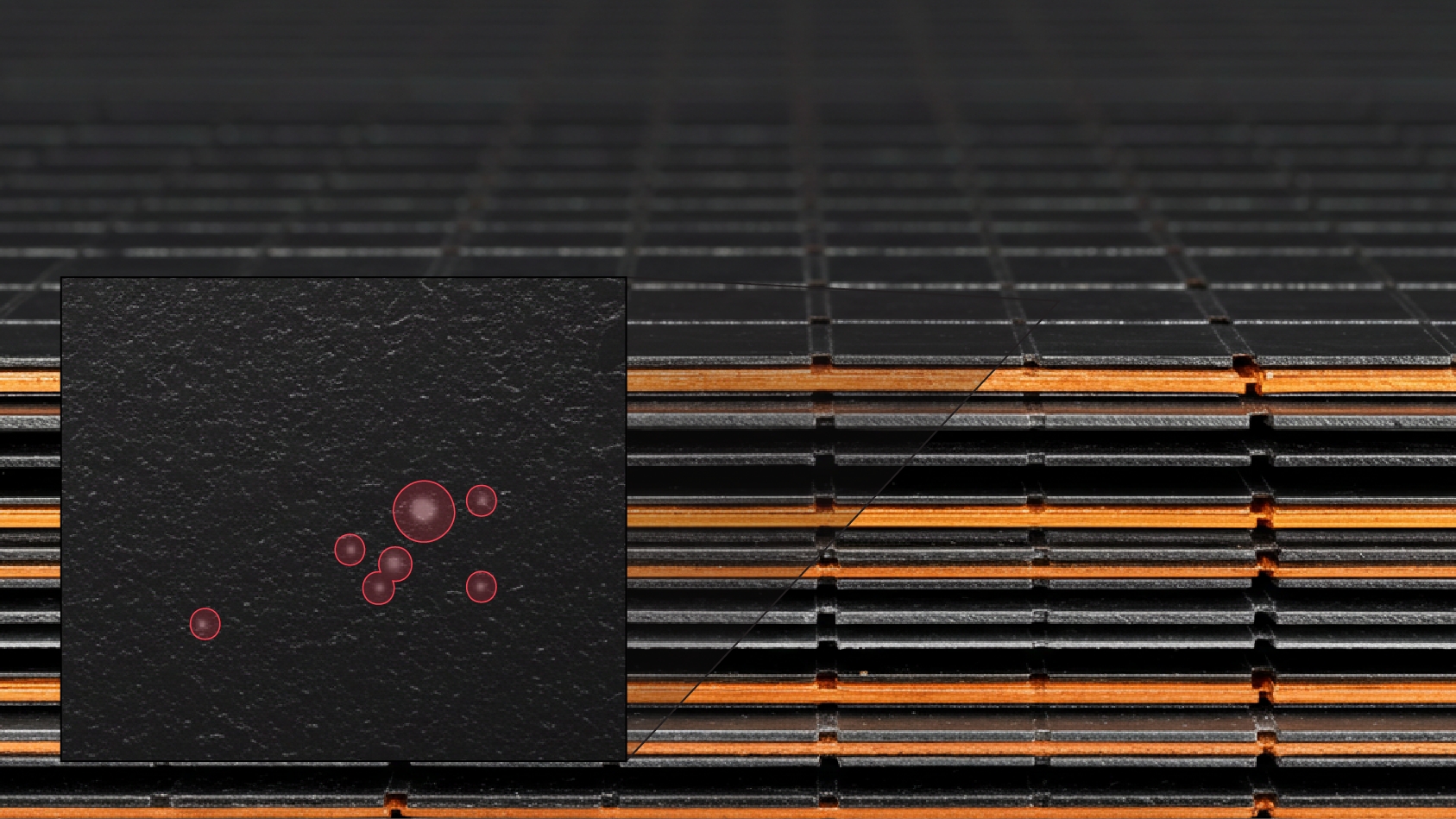

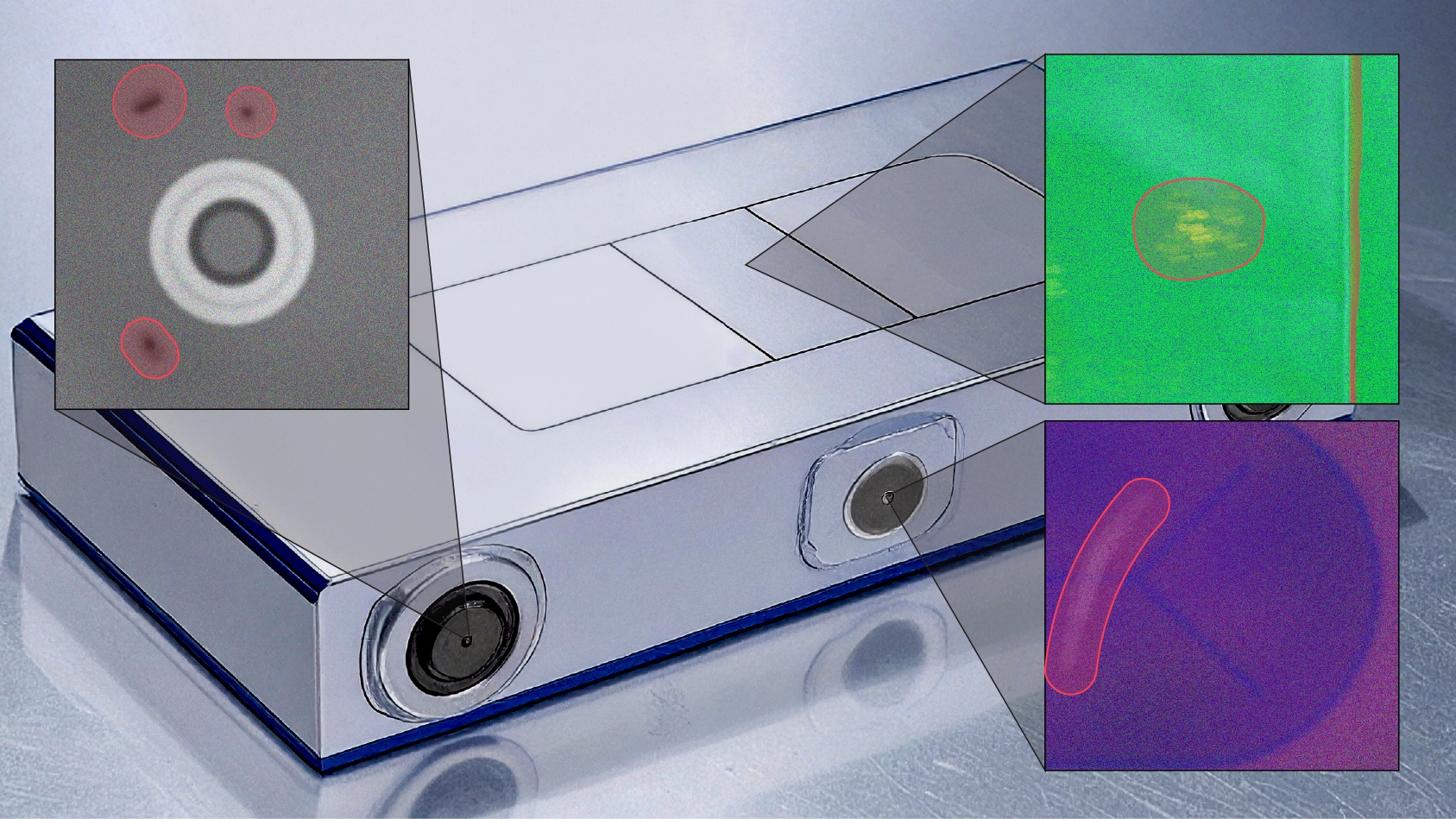

Stacking Process

-

-

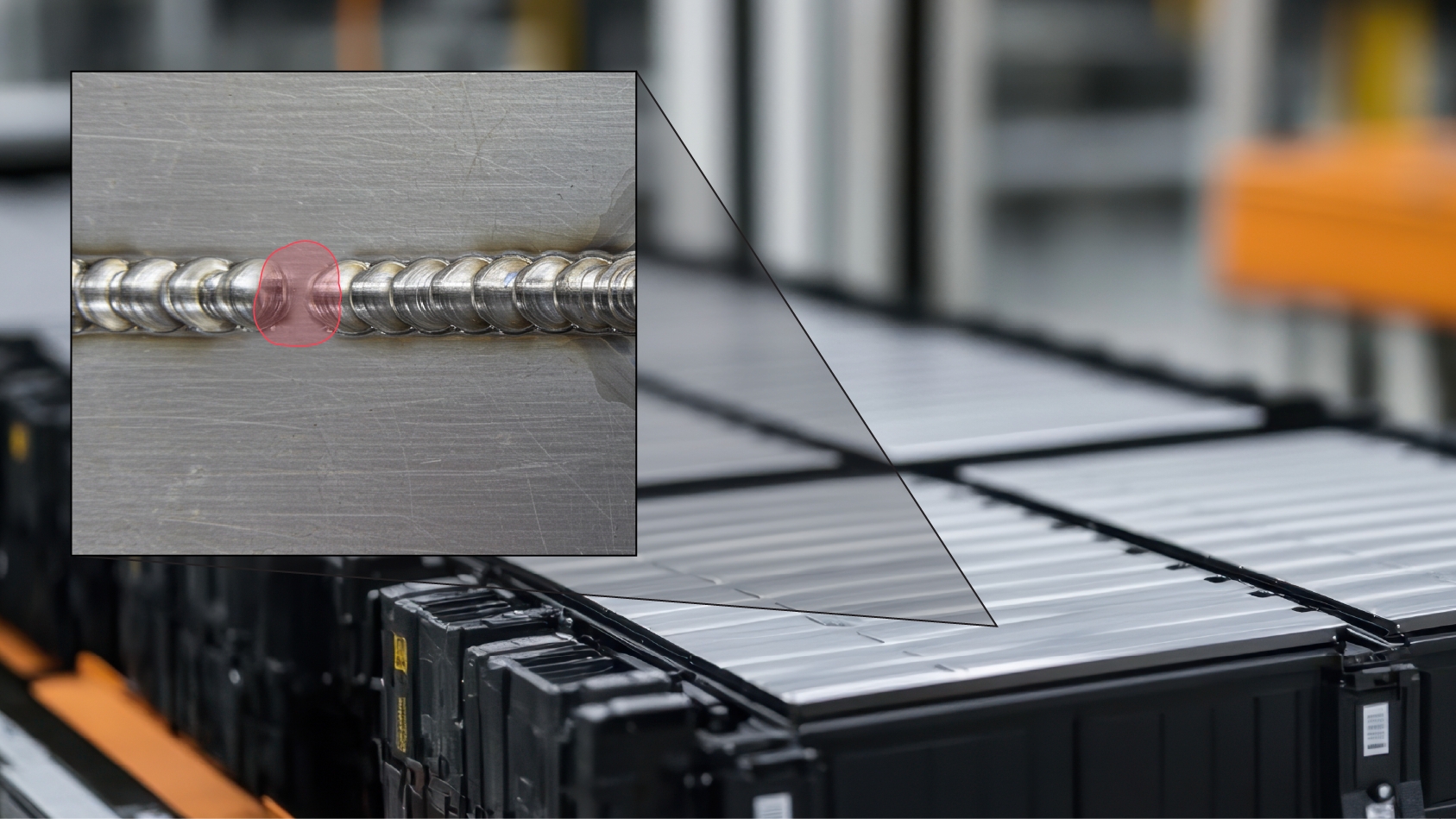

Assembly Process

-

-

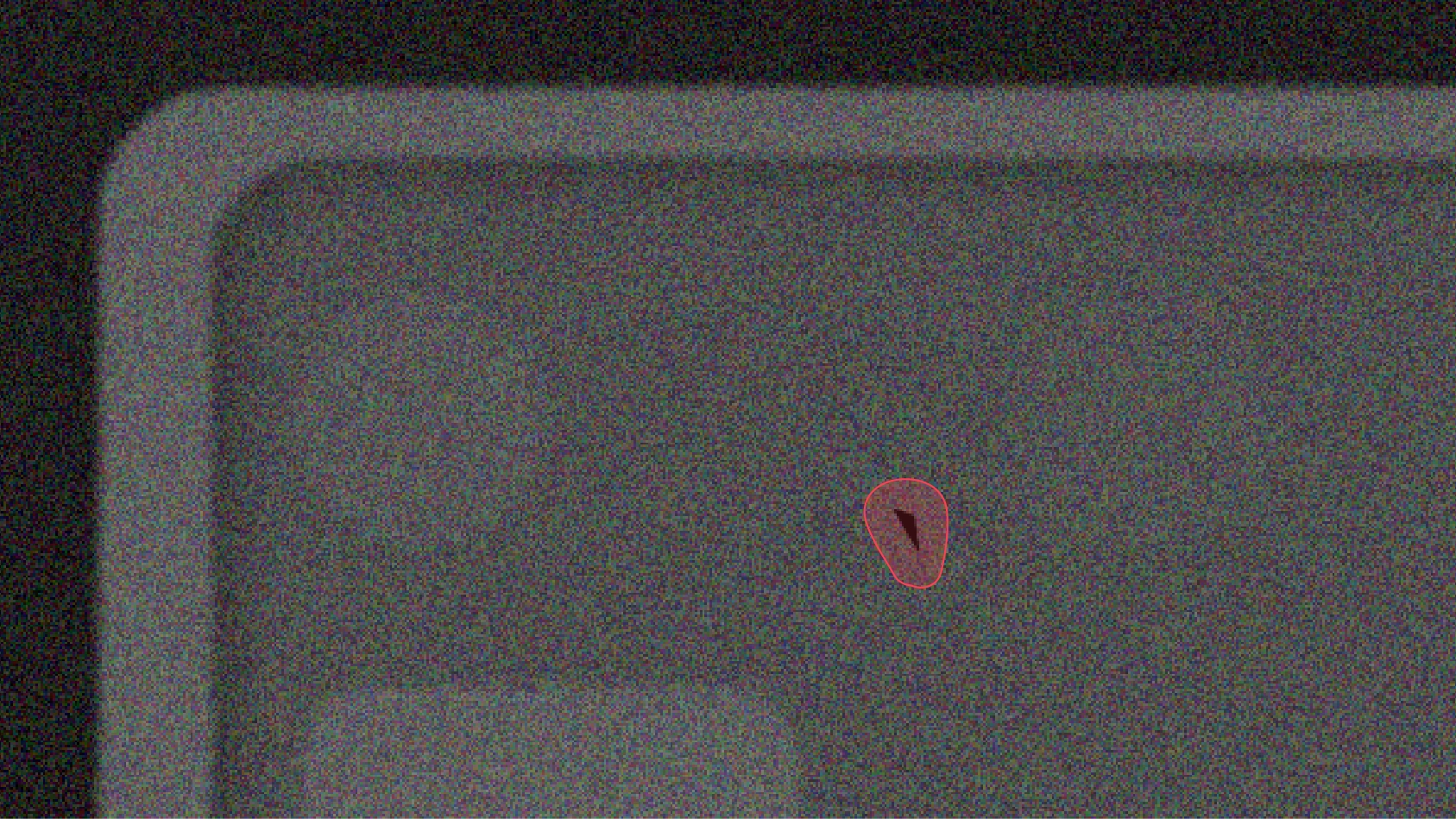

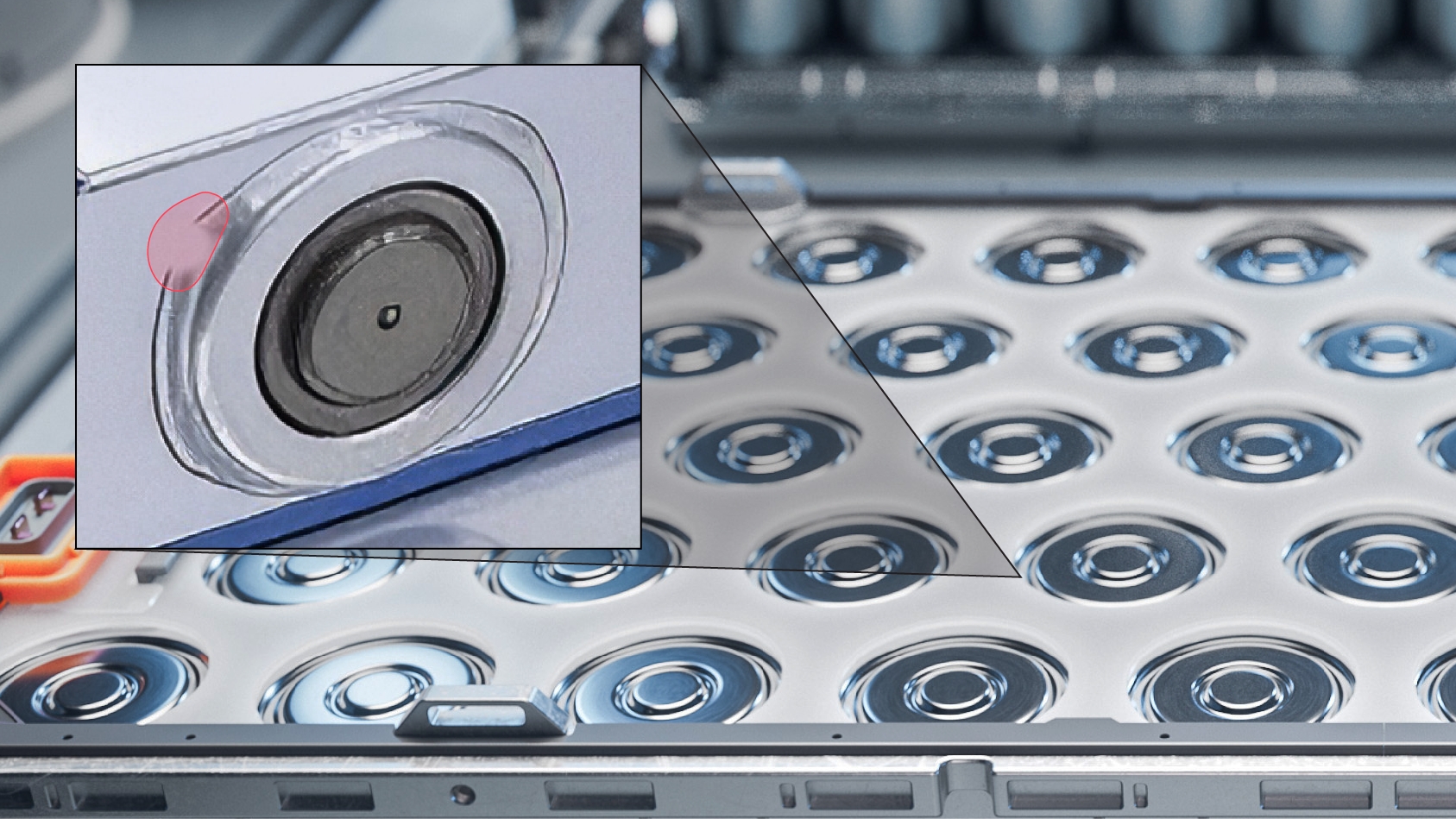

Formation Process

-

-

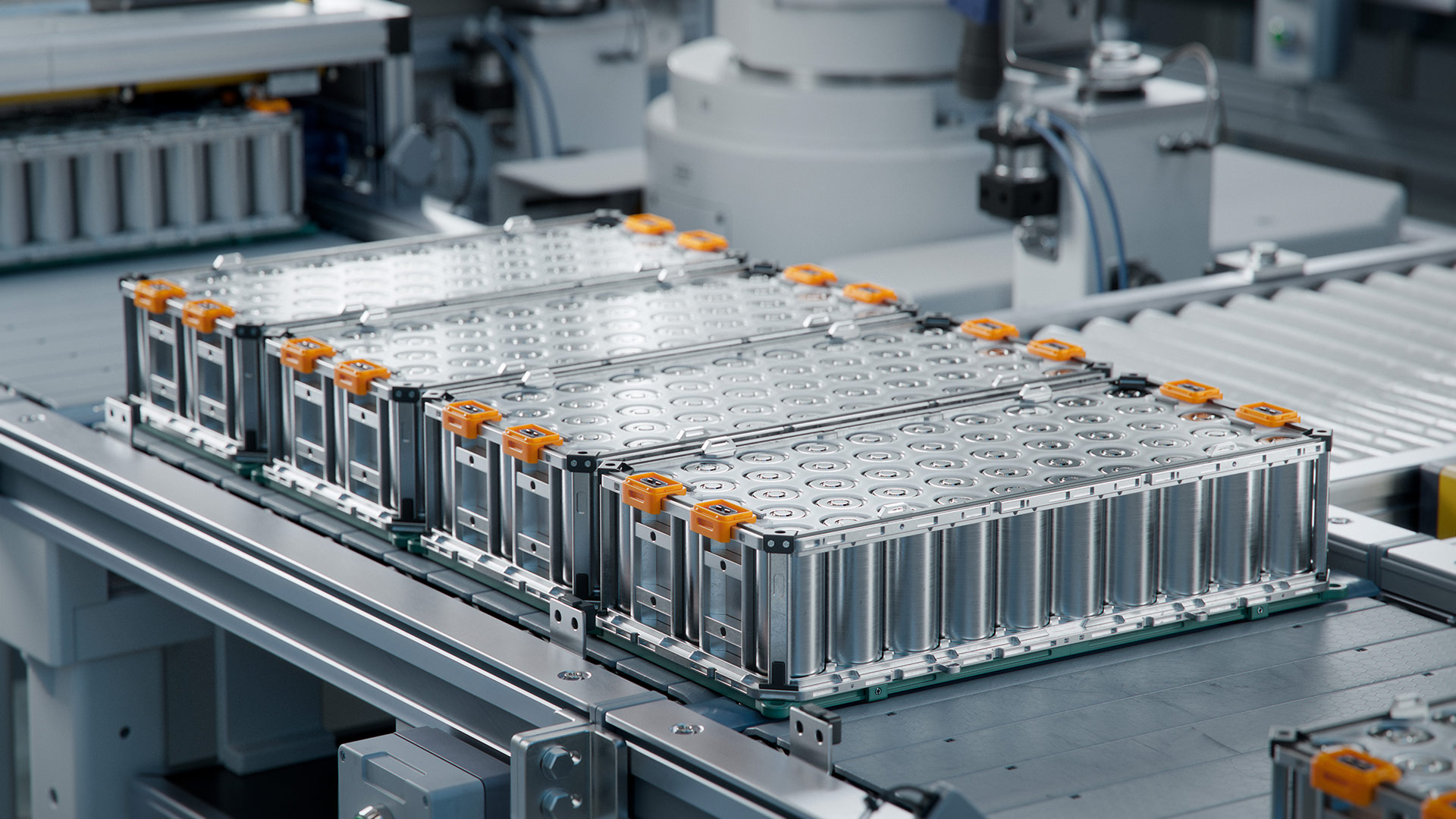

Module/Pack Process

-

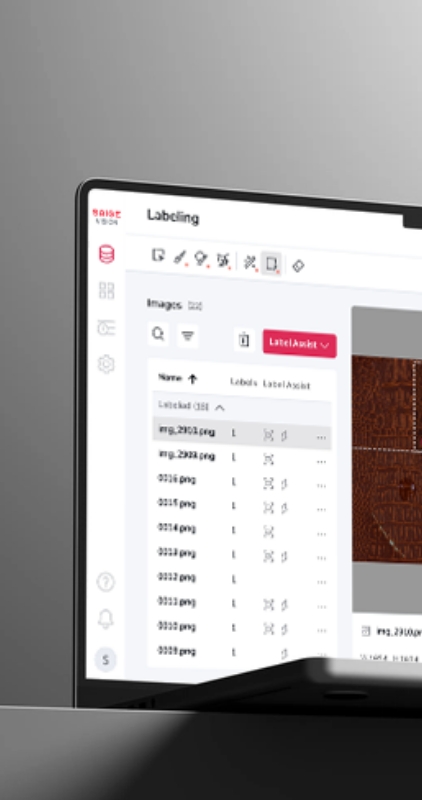

USP

SAIGE’s technology that

SAIGE VISION" />

SAIGE VISION" />