client

Introduction

Superior Performance, Easy Operation,

Superior Performance, Easy Operation,

Minimal Maintenance

Workflow

All-in-one Solution

All-in-one Solution

for Automated Machine Vision Inspection

Impact

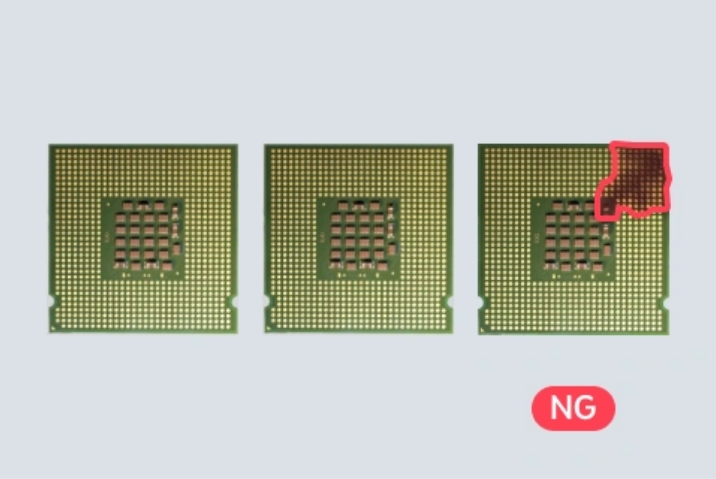

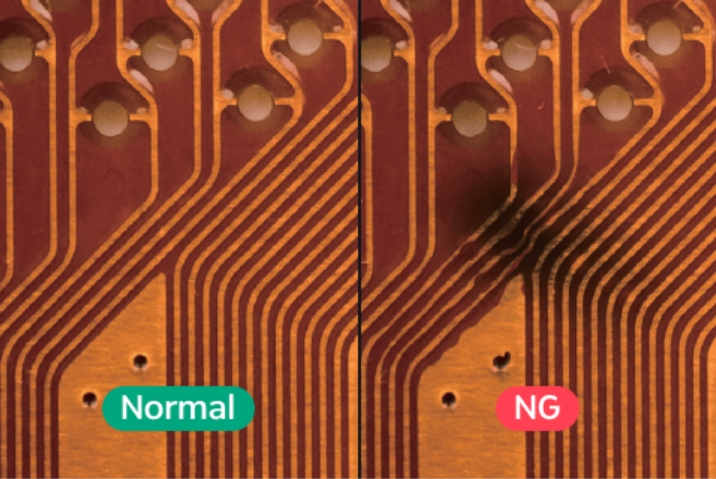

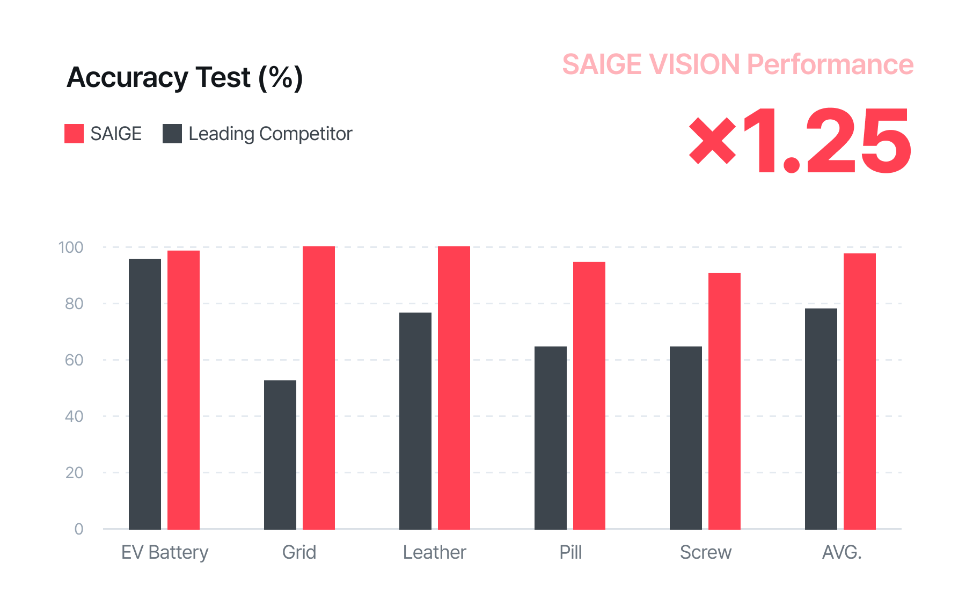

AI Vision Inspection achieves more than perfect detection.

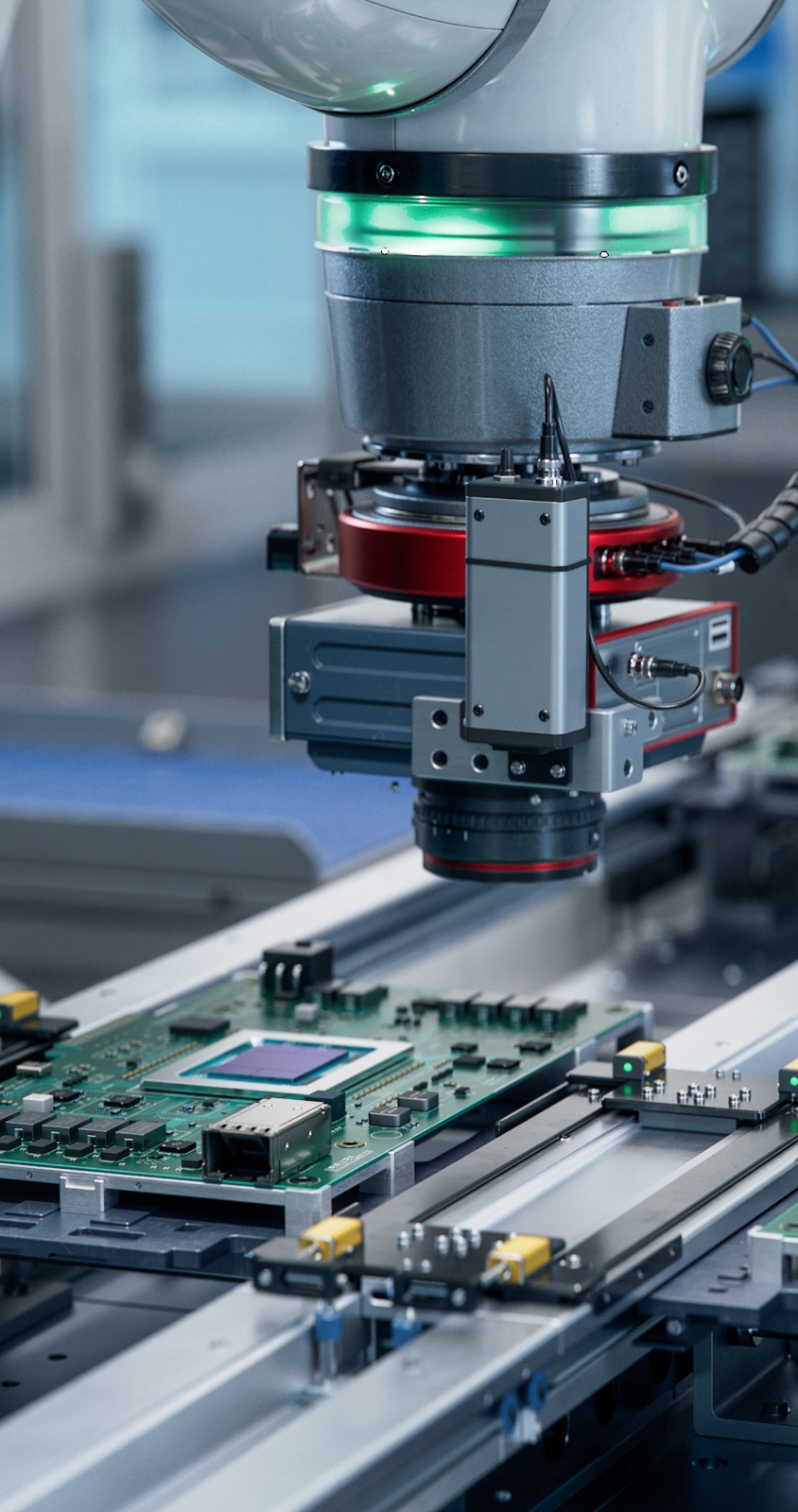

Applications

SAIGE VISION

SAIGE VISION

can be applied across various industries.

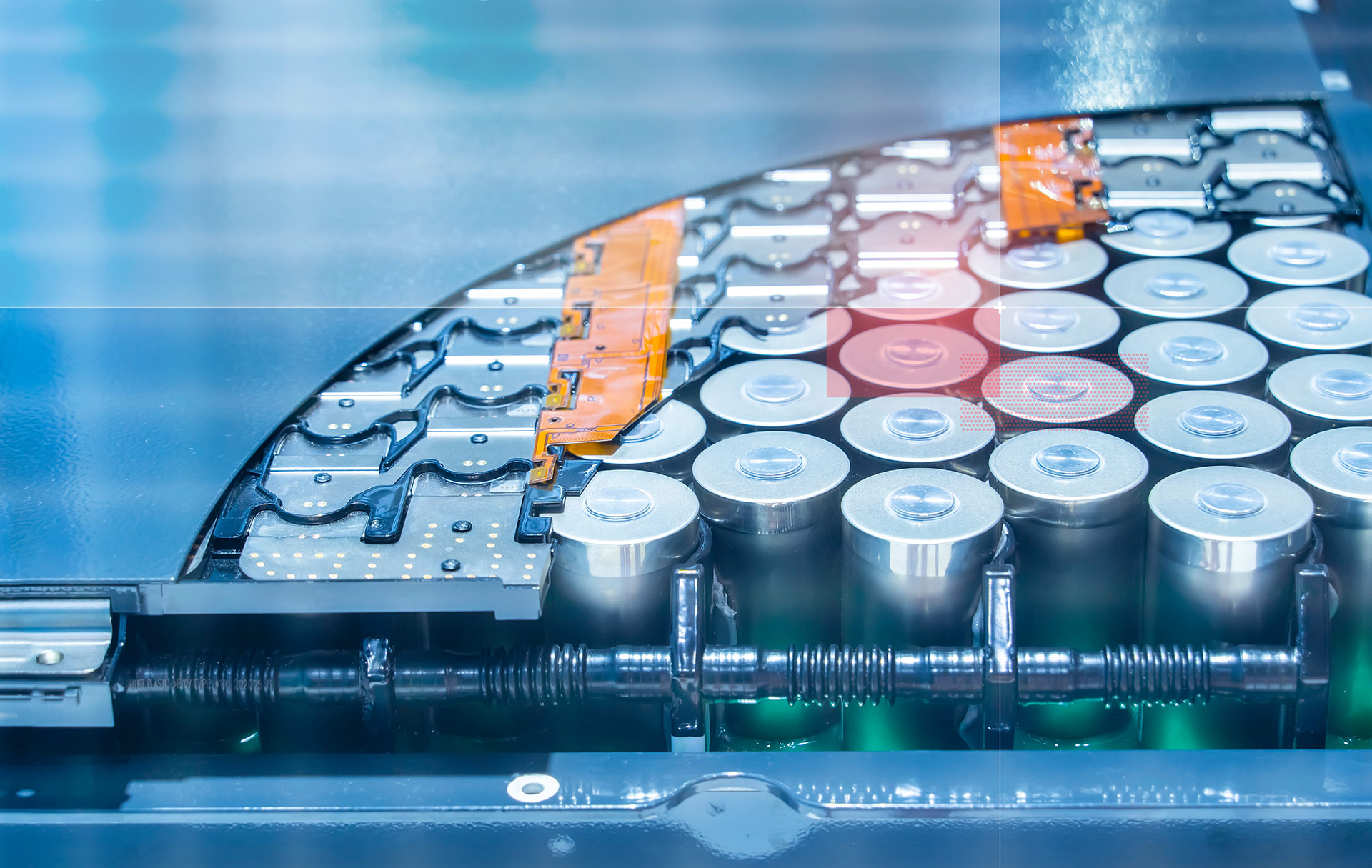

- Rechargeable Battery

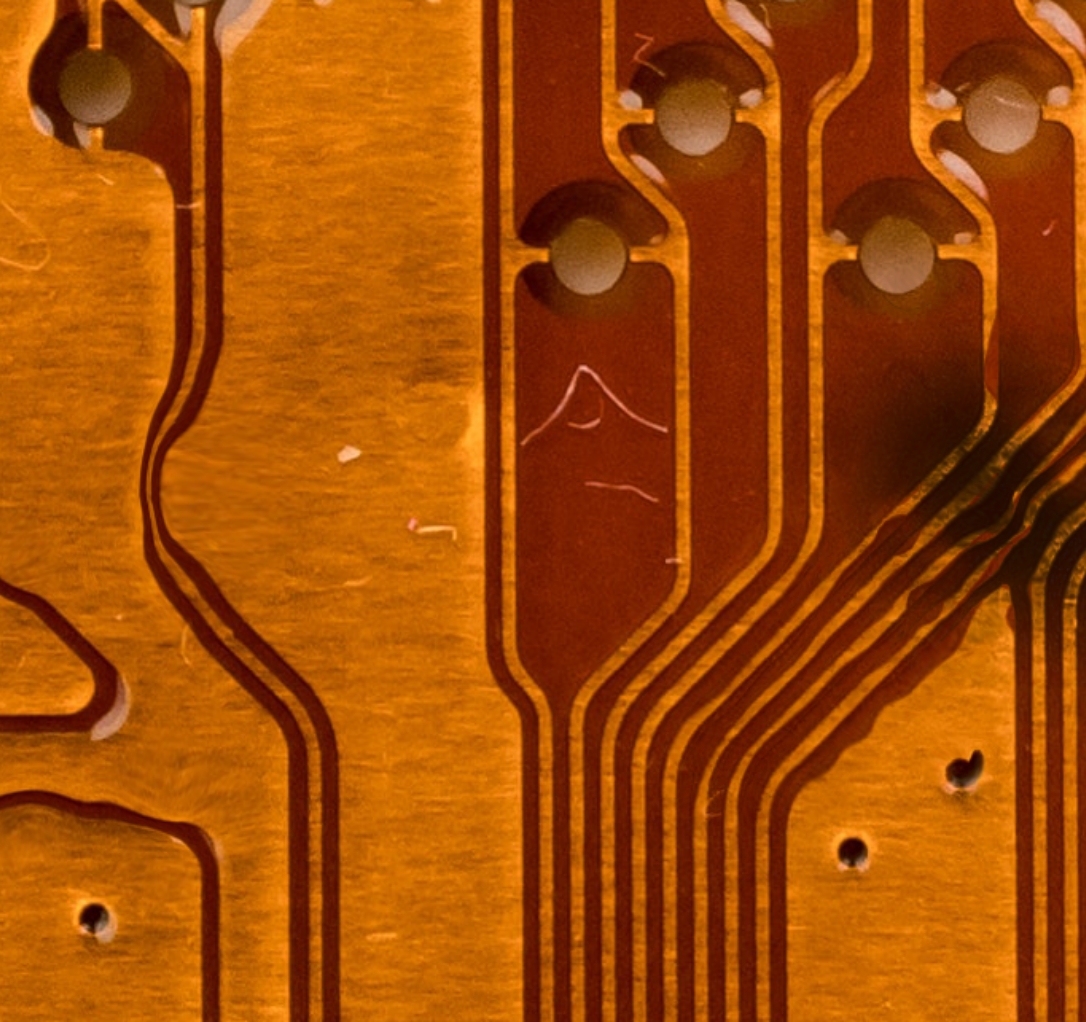

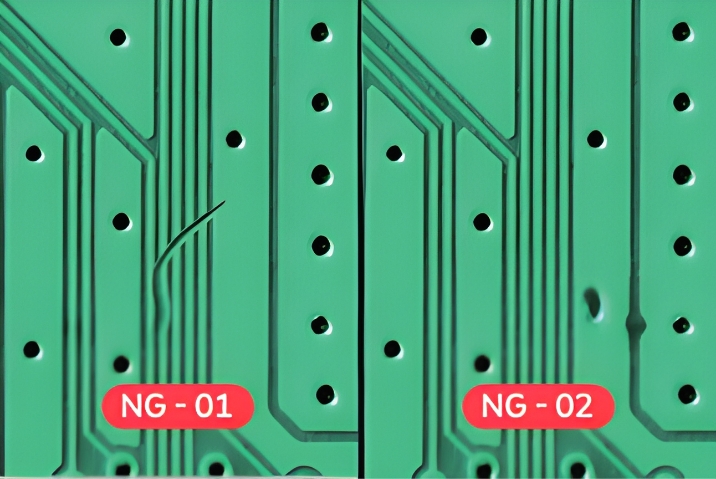

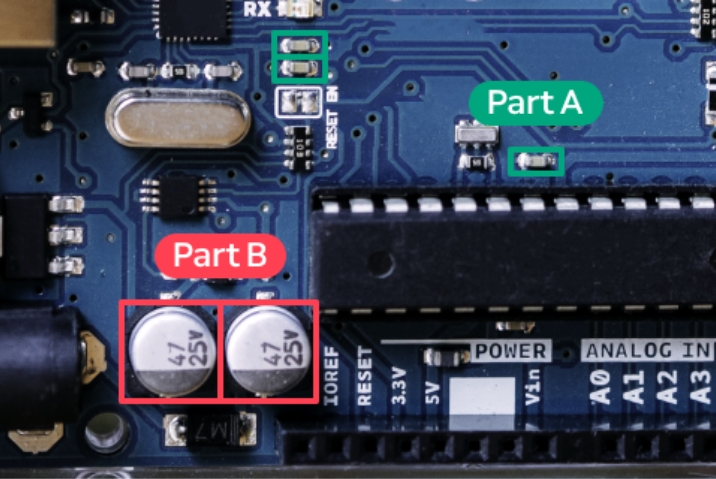

- PCB

- F&B

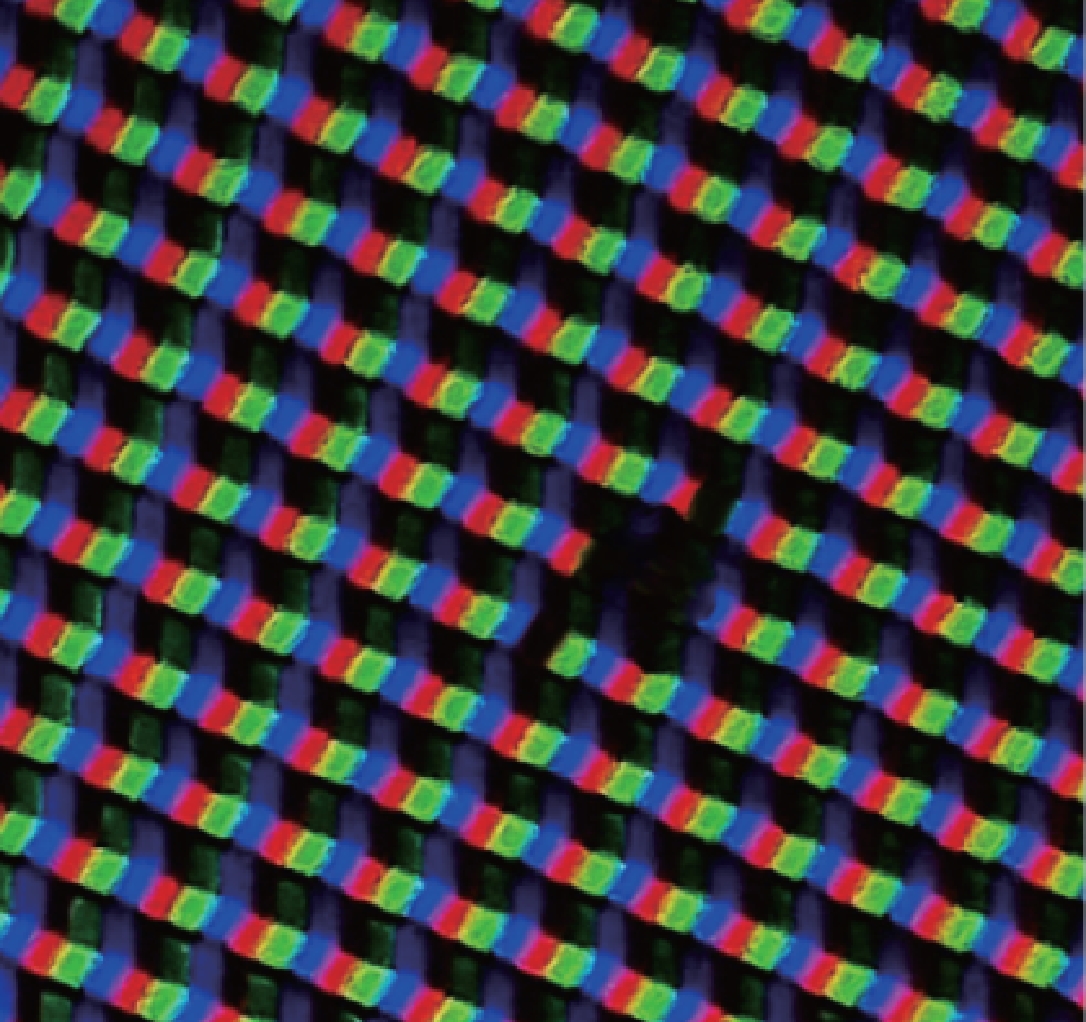

- Display

- Printing

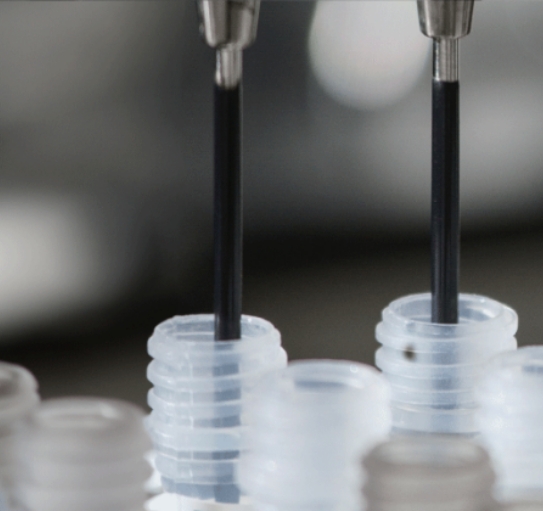

- Biopharmaceuticals

- Automotive

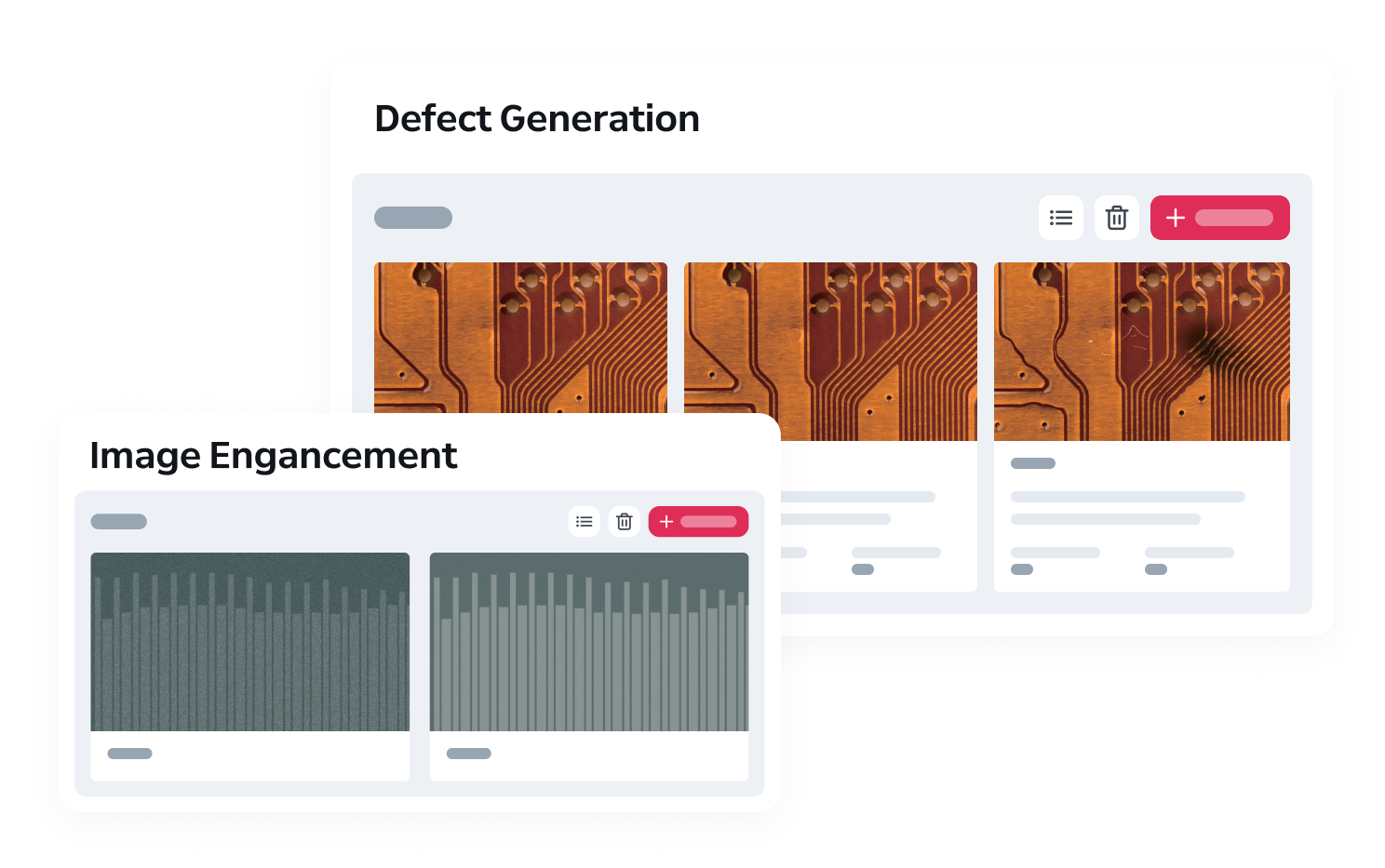

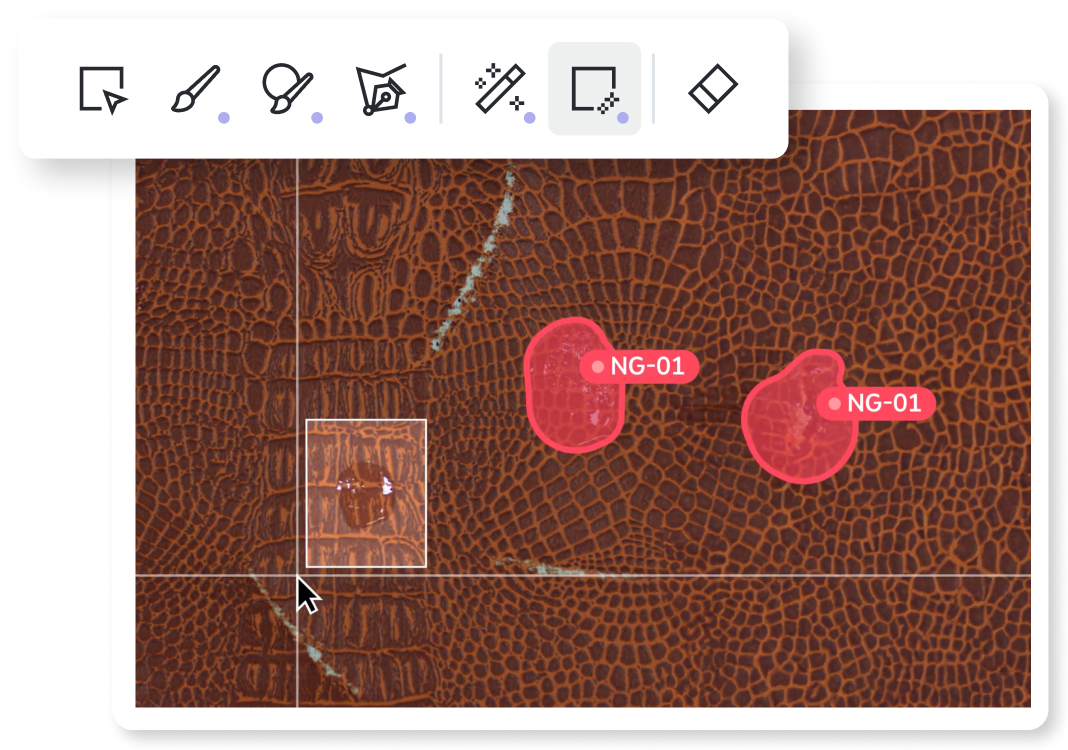

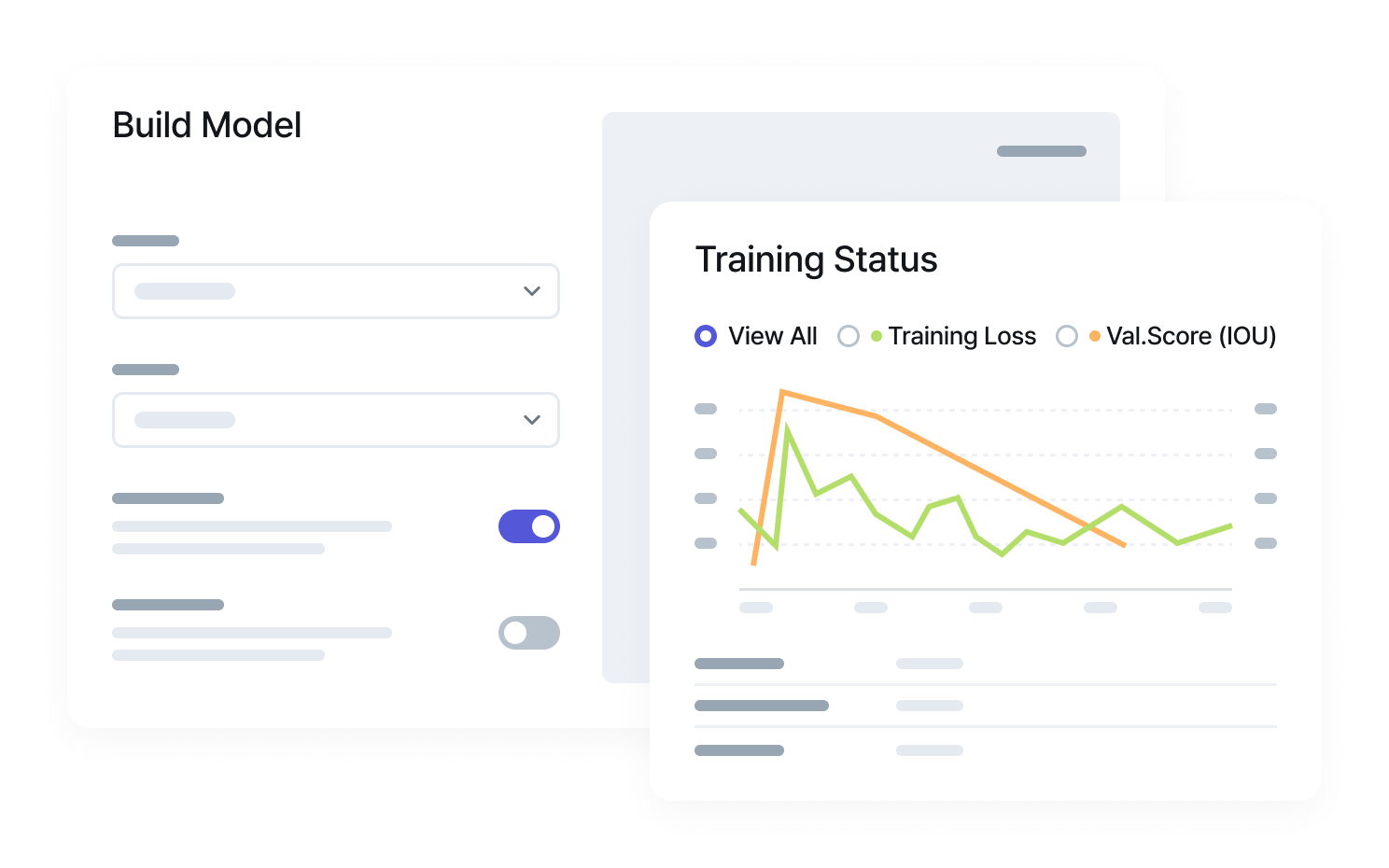

Functions

Explore the Core Features

Explore the Core Features

of SAIGE VISION

Key Features

Special Features

Strength

Discover What Makes